ABC Co-Extruding Rotary Head Film Blowing Machine

Machine Information:

The three-layer co-extruded PE heavy packing film has excellent properties which cannot be compared with the three-layer PE film.

It has extensive selectivity in the application of materials and can fully reflect the functions of different levels.It is widely used in the

packaging of chemical raw materials, grain, fertilizer and other bulk products. It is suitable for the production of all kinds of heavy

packaging bags, carrying bags and garbage collecting bags. It can also be used as printing and composite basic materials.This type

of film blowing machine is mainly for making DHL courier bags, lamination film, agriculture film etc

1.Main machines are all equipped with frequency converter from Japan Yaskawa control.

2.Die head adopts new international advanced technology for stacking, conical and

streamline surface.

3.Winding and Unload System adopts automatic friction and tension control.

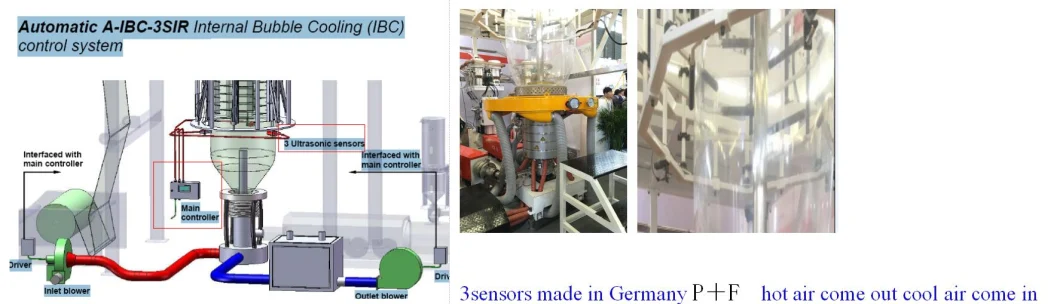

4.IBC system adopts ultrasonic control for internal bubble cooling, and equipped with anew type of motorized electric squirrel-cage bubble stabilizer. this system adopts ultrasonic sensors to pass the signal to computer. By adjusting the speed of air blower that exchanged cool and hot air in the bubble, so as to ensure the size of bubble fold diameter. The IBC internal bubble cooling system improves film quality and transparency, finally increases the output

EPC photoelectron correct errors system can correct automatically, which ensures the roll film evenly.

Winding and Unload System adopts automatic friction and tension control.

PLC from Japan Mitsubishi brand for centralized control.?

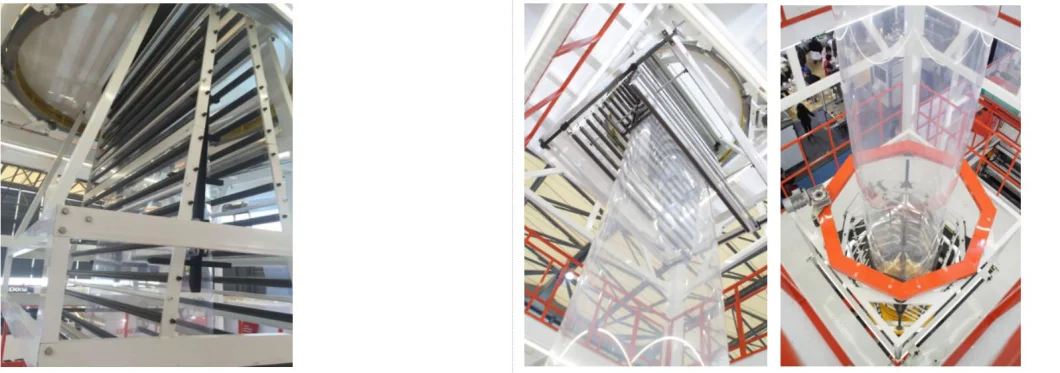

Traction System makes the horizontal ± 360° reciprocation rotation. It solves problems of leakage, poor sealing and maintenance and improves the quality of film.

Flying cutting knife cut the film automatically.

Tension sensor for auto tension control

Unfold film cutting knife

Waste edge film recycle by automatic

Machine Parameter:

| Film layflat width | 1200-1700mm | |||

| Film thickness: | 0.028-0.15mm | |||

| Film Thickness Tolerance | ≤±8% | |||

| Film structure: | three-layer co-extrusion A(out layer) /B/C(inner layer) | |||

| Raw materials | LDPE,LLDPE,mLLDPE | |||

| Reel diameter | Max.φ600mm | |||

| Max.production capacity | 280kg/hr | |||

| Total power | approx. 280kW | |||

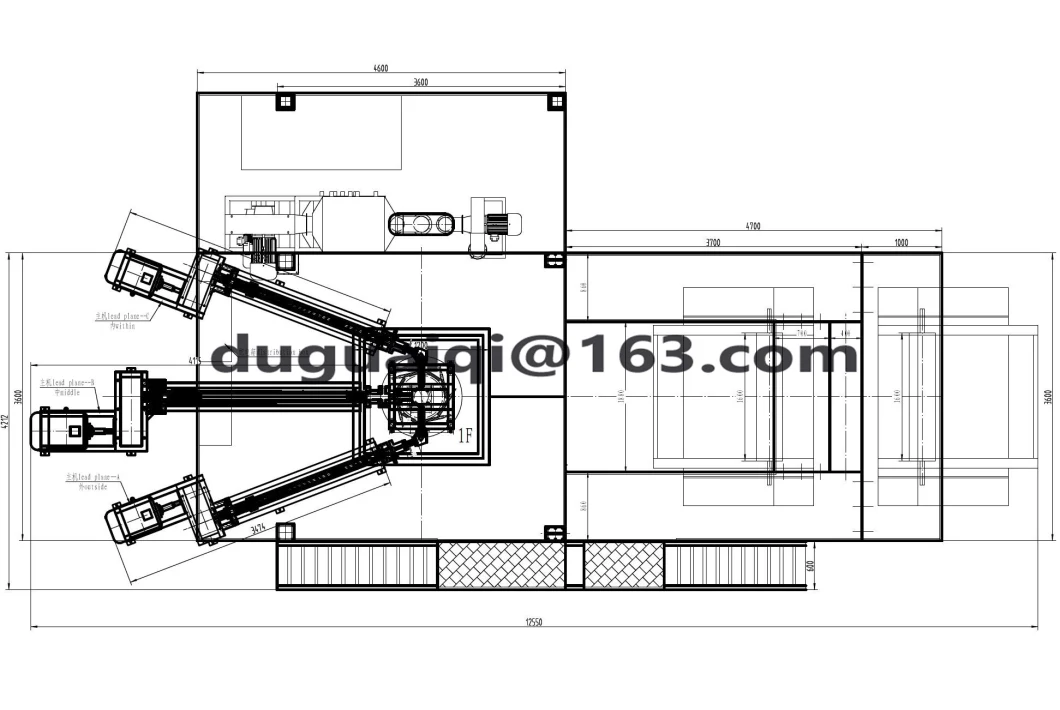

| Line outer dimensions(L×W×H) | 10×6.5×11.5m | |||

| Line weight | approx. 26t | |||

| EXTRUDER | 3 sets | |||

| SCREW DIAMETER (mm): | Φ65mm 3set; | |||

| L/D ratio: | 32:1 | |||

| Screw Material/Barrel Material: | 38 CRMOALA | |||

| Max. screw rotating speed: | 100r/min | |||

| Barrel HEATING AREAS: | 4+5+4 AREAS, | |||

| Barrel cooling blower | 550w×3 SET,×3 INSTALLED OUTSID | |||

| FEED DEVICE COOLING: | WATER CIRCUALTING | |||

| Extruder main motor: | A45kw 3set YASKAWA INVERTER, MOTOR:SIEMENS BEIDE | |||

| SCREEN CHANGER | MANUAL SCREEN CHANGER | |||

| Heating Capacity | 3SETS | |||

| With domestic melt pressure and temperature sensor before screen changer,3 sets | ||||

| Gear box | 3SETS | |||

| DIE: | ||||

| DIE SIZE | LD Φ400mm:1SET ABA DIE HEAD | |||

| Temperature Control Zone | 4ZONES | |||

| Heating Capacity : | 40kw | |||

| Air ring | DIAMETER1400 mm double lips air ring | |||

| Inner bubble cooling system | YES | |||

| Air blower for IBC | 5.5kw×2pcs,(INVOANCE INVERTER) | |||

| HEIGHT OF AIR RING: | 130mm | |||

| WIND PIPE: | Φ80×6 | |||

| AIR BLOWER: | 11kw INVOANCE INVERTER | |||

| ||||

| TAKE-UP UNIT | ||||

| ||||

| ROTARY TAKE-UP TOWER: | Yes ±360° | |||

| PINCH ROLLER: | Φ165×1800mm, THICKNESS=8mm (Air-pressure) | |||

| TAKE UP ROLLER | 1pc silicon roller 1 pc steel roller | |||

| ELECTRICAL CONTROLLER SYSTEM: | 1.5kw+WORM GEAR REDUCER(INVOANCE INVERTER) | |||

| TAKE-UP SPEED: | 5-60m/min | |||

| GABLE: | Aluminum | |||

| ||||

| FOAM STABILIZING EQUIPMENT: | HEIGHT AND SIZE ADJUSTED BY ELECTRONIC MOTOR | |||

| Collapser adjusting method: | manual motion | |||

| GUIDING STICK: | Φ100×1800mm | |||

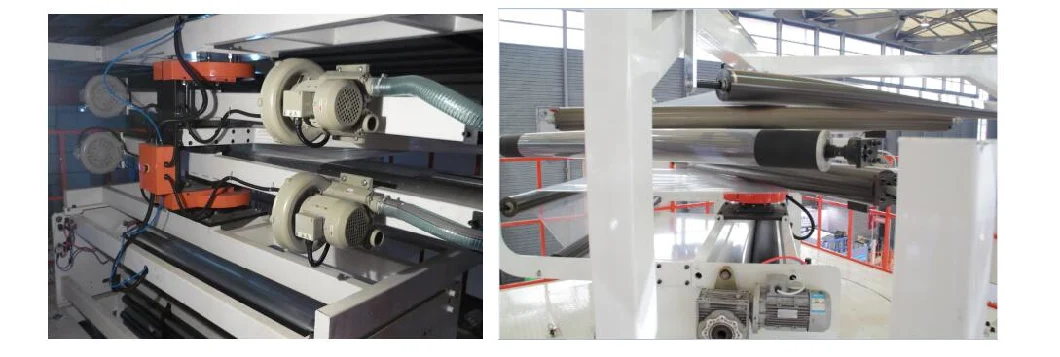

| WINDING | ||||

| With 3 tension system | ||||

| THE WINDER PROGRAM IS CONTROLLED BY PLC,HUMAN MACHINE INTERFACE. | ||||

| WINDING TYPE | AUTOMATIC BACK TO BACK REWINDER | |||

| Hydraulic pump for unloading roller | YES | |||

| PINCH ROLLER FOR SECOND TIME: | Φ165×1800mm | |||

| ELECTRICAL CONTROLLER SYSTEM: | 1.5kw+ WORM GEAR REDUCER(INVOANCE INVERTER) | |||

| SLITTING KNIFE: | DOUBLE KNIVES | |||

| Bowed roll | 5pcs | |||

| MAX DIAMETER OF WINDER: | 600mm | |||

| MOTOR&CONTROLLER SYSTEM: | 1.5kw WITH INVOANCEINVERTER | |||

| WINDING STICK: | Φ74 AIR SHAFT ×4PCS | |||

| WINDING ROLLER: | Φ330× 2PCS | |||

| Electronic edge guide (EPC) E+L | YES, MADE IN GERMANY | |||

| ||||

| TENSION CONTROLLER | YES | |||

| SWITCH BOX | ||||

| CONTACTOR: | Siemens | |||

| TEMPERATURE CONTROLLER: | DIGITAL DISPLAY(EBPM) | |||

| Remote monitoring interface | YES | |||

| INCLUDED EQUIPMENTS | ||||

| IBC | YES | |||

| TAKE-UP ROTARY | YES | |||

| EPC E+L (GERMANY) | YES | |||

| AUTOMATIC DOUBLE SIDE REWINDER WITH UNLOADER AUTOMATIC | YES | |||

Machine Show:

Sample Show:

Contact Details

WENZHOU RUNHAI MACHINERY CO.,LTD

RUIAN ZHECHUANG INTERNATIONAL TRADE CO.,LTD

Ms.Linly

Cell: 0086-13736789004

runhaimachine.en.made-in-china.com